The advancement of semiconductor technology within India reached a major goal by creating native semiconductor chips intended for aerospace missions. Through their partnership, IIT Madras (IIT Madras) along with ISRO (Indian Space Research Organisation) created the IRIS (Indigenous RISC-V Controller for Space Applications) chip that utilizes SHAKTI microprocessor foundations. The program implements the 'Make in India' and 'Atmanirbhar Bharat' programs.

Indigenous Semiconductor Breakthrough

-

The aerospace application field saw a major technological advancement for semiconductors within Indian borders.

-

IIT Madras joined forces with the Indian Space Research Organisation to establish IRIS (Indigenous RISC-V Controller for Space Applications).

-

The chip depends on SHAKTI microprocessor momentum while using RISC-V technology as an open-source solution.

SHAKTI Microprocessor & RISC-V Technology

-

Professor V Kamakoti at IIT Madras PSCDISHA Center oversees the SHAKTI project.

-

RISC-V functions as an open-source processor architecture that receives support through the ‘Digital India RISC-V’ (DIRV) initiative.

-

The initiative works to establish an autonomous processor system for vital program requirements.

Key Features of IRIS Chip

-

This microprocessor system has been created specifically for command and control systems used by ISRO.

-

This processor benefits from design features that promote reliability and tolerate system faults so it works efficiently for space operations.

-

The chip includes feature-specific built-in modules that integrate serial buses with WATCHDOG timers.

-

Features multiple boot modes and hybrid memory extensions for future expansion.

-

This domestically produced technology enables India to be independent in its semiconductor developments.

Expansion of 'Make in India' and 'Atmanirbhar Bharat'.

-

The development team consisted of IIT Madras together with IISU Thiruvananthapuram.

-

The 180 nm technology node manufacturing process was implemented at Semiconductor Laboratory (SCL) Chandigarh to produce the device.

-

The chip packaging process takes place at Tata Advanced Systems located in Karnataka state.

-

The manufacturing of the motherboard takes place in Gujarat before Tata Airports assembles it in Chennai.

-

Software Development & Booting at: IIT Madras.

Indigenous Development of Semiconductors

What are Semiconductors?

-

Materials with conductivity between conductors and insulators.

-

Materials used in semiconductor chips include both pure elements silicon and germanium together with compounds of gallium arsenide.

-

The resistance of materials lies between the values of insulators and conductors.

-

The resistance value declines when the temperature rises.

Importance of Semiconductors

-

Core of Modern Technology – Used in electronics, communications, automobiles, and medical devices.

-

Propels Emerging Technologies – Essential for AI, 5G, and autonomous vehicles.

-

The Value of Global Trade with Semiconductors stands as the second highest after automotive and fuel sectors.

-

Reduction in device scale and improvement in efficiency and cost-effectiveness happens through semiconductor assistance.

-

Transformative Potential – Drives progress across industries such as aerospace, consumer electronics, and healthcare.

India’s Current Status in Semiconductor Manufacturing

-

The R&D sector for semiconductors exists in India because various international businesses operate research facilities inside the country.

-

Two strategic fabrication plants are operating in India for defense and space sector needs under DRDO’s SITAR and SCL Chandigarh.

-

India imports all its commercial chips from foreign vendors while China remains its primary supplier (100% imports) during 2020.

Significance of Indigenous Semiconductor Development in India

-

An independent supply chain enables India to lower its import dependence.

-

The growing number of remote workers and internet users within India requires the development of indigenous semiconductors to meet their demand.

-

Manufacturing within India creates employment opportunities that also enhance electronics value chains and produce various positions.

-

The indigenous production of semiconductors enables India to save import expenses and create more export opportunities.

-

Security benefits increase when processing happens locally because production takes place within the nation.

-

Geopolitical Leverage gives India the ability to decrease Chinese imports while enhancing its international leadership position.

-

Increased Competitiveness – Enhances India's position in global semiconductor manufacturing.

Challenges in India's Semiconductor Industry

-

The capital requirements for starting a fab unit amount to between $5 to $7 billion.

-

The investment process suffers delays and requires various government clearances to proceed because of bureaucratic inefficiencies.

-

Unstable Power Supply – Requires uninterrupted power, available in limited regions.

-

Advanced semiconductor technologies present technological barriers because they require high licensing expenses.

-

Structural problems exist in India because the availability of skilled workers is low land acquisitions take too long and tax stability remains unclear to foreigners.

Government Efforts Toward Semiconductor Industry Development

-

The National Policy on Electronics from 2019 functions to develop Electronics System Design and Manufacturing (ESDM) into a global hub for India.

-

The Semicon India Programme receives INR 76,000 crore for semiconductor and display production.

-

Modified Semiconductor Fabs Scheme – Provides 50% fiscal support for semiconductor wafer fabrication.

-

Modified EMC 2.0 Scheme – Supports the establishment of Electronics Manufacturing Clusters (EMCs).

-

100% FDI in Electronics Manufacturing – Encourages foreign investment in the sector.

-

Production Linked Incentive (PLI) Scheme – Provides financial incentives for domestic manufacturing.

Way Forward

-

Adequate Funding for R&D – Support institutions for innovation in semiconductors.

-

The SPF program should be rapidly deployed as a sovereign patent fund to buy domestic business patents.

-

Manufacturers will join domestic markets when manufacturers receive guarantees of domestic purchasing requirements.

-

The nation should provide support for semiconductor companies to acquire operational units based abroad.

-

Manufacturing facilities should start with packaging and testing procedures before establishing complete fabrication operations.

-

The states should work together with the government to provide reliable power supply and clean water access.

Conclusion

Increasing demand for semiconductor chips will persist because the digital revolution maintains its fast pace. Self-reliance combined with economic development plus global leadership requires India to prioritize domestic semiconductor manufacturing. The implementation of appropriate funding measures and nationwide policy improvements will establish India as a prominent semiconductor industry force on a worldwide scale.

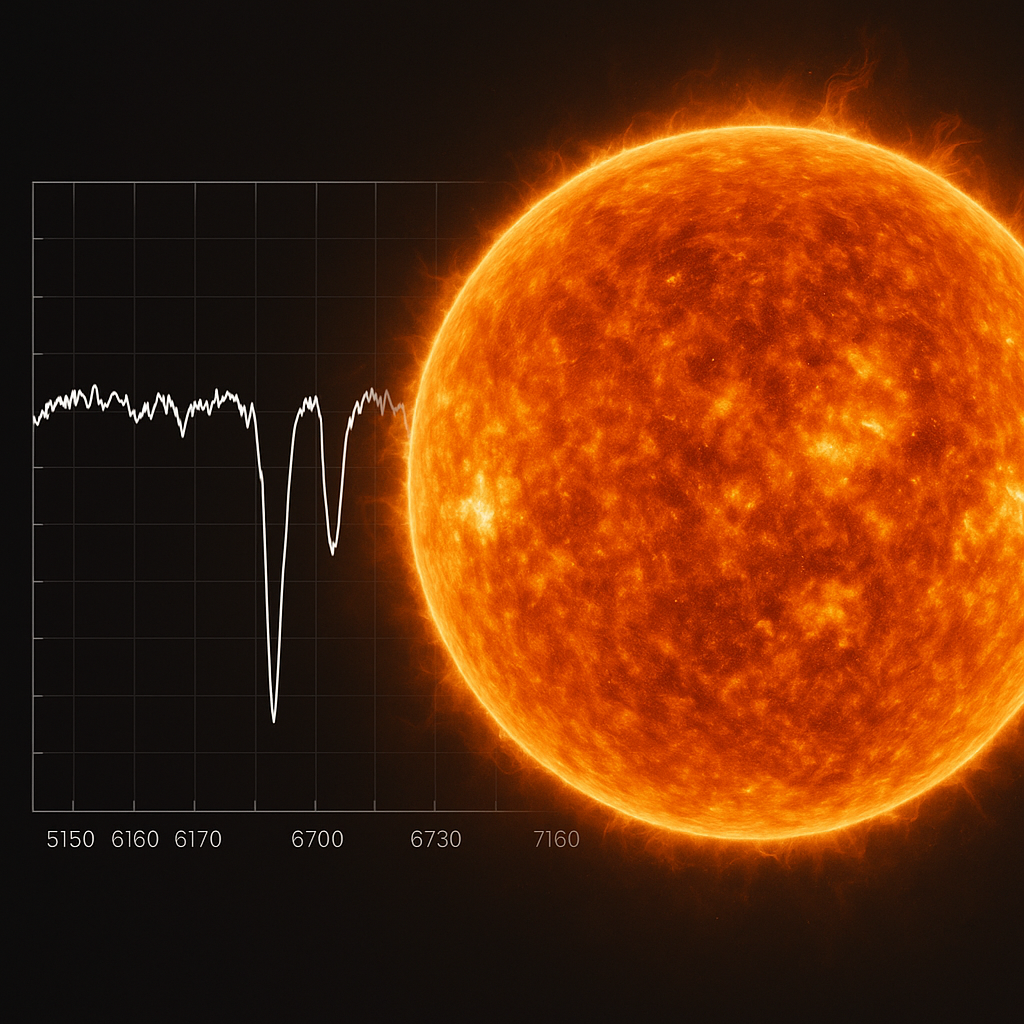

IIA Achieves Breakthrough in Measuring Helium Abundance in the Sun

IIA Achieves Breakthrough in Measuring Helium Abundance in the Sun QpiAI Launches India’s First Full-Stack Quantum Computer, QpiAI-Indus, on World Quantum Day

QpiAI Launches India’s First Full-Stack Quantum Computer, QpiAI-Indus, on World Quantum Day ISRO to Send Tardigrades on Axiom-4 Mission: A Step Towards Advancing Space Research

ISRO to Send Tardigrades on Axiom-4 Mission: A Step Towards Advancing Space Research TERI's Nano Sulphur Breakthrough in Mustard Cultivation

TERI's Nano Sulphur Breakthrough in Mustard Cultivation ISRO's Successful Second Docking of Satellites – A Milestone in Space Technology

ISRO's Successful Second Docking of Satellites – A Milestone in Space Technology Potential Biosignatures Discovered on Exoplanet K2-18b by JWST

Potential Biosignatures Discovered on Exoplanet K2-18b by JWST India Launches First Native Seed Germination Database for Ecological Restoration

India Launches First Native Seed Germination Database for Ecological Restoration India’s Evolving Approach to Artificial Intelligence Governance and Regulation

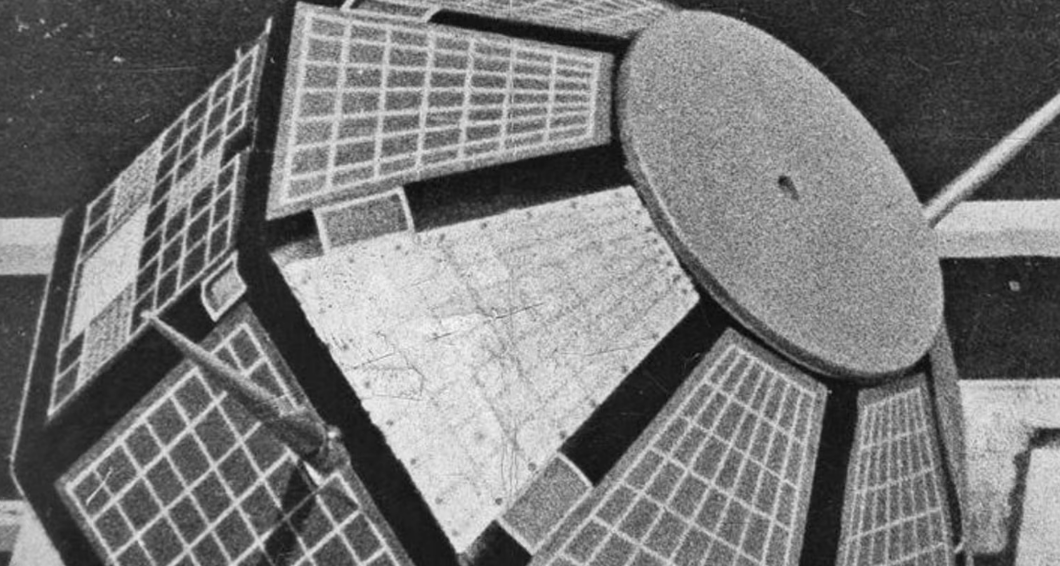

India’s Evolving Approach to Artificial Intelligence Governance and Regulation Golden Jubilee of Aryabhata 2025: Celebrating India’s First Satellite and ISRO’s Historic Milestone

Golden Jubilee of Aryabhata 2025: Celebrating India’s First Satellite and ISRO’s Historic Milestone ESA's Biomass Mission 2025: Tracking Global Forest Carbon Storage via Satellite

ESA's Biomass Mission 2025: Tracking Global Forest Carbon Storage via Satellite